Opta has vast hands-on experience with various hardware and software, and we can provide solutions for each customer’s preferred operating system. We engineer every component for simple, safe, and efficient operation, and we provide complete, ongoing training and technical support.

ENGINEERING & EQUIPMENT

RELIABLE EXPERTISE

Opta has expertise in the design, fabrication, and installation of multiple systems and equipment options for the steel industry, including cored-wire injection systems, desulfurization stations, pneumatic-injection equipment, and bulk-handling systems.

We offer injection and bulk-handling equipment as well as wire feeder equipment and engineering.

Opta supplies reliable equipment and engineered solutions to the steel industry.

We approach every project we undertake with customized service and unparalleled support. Our commitment to long-term customer relationships ensures optimum reliability. Opta field service technicians are available around the clock to perform preventive and emergency maintenance.

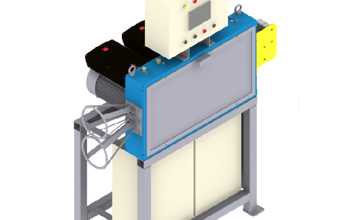

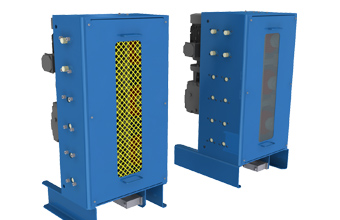

Injection and Bulk-Handling Equipment

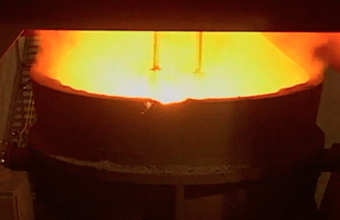

Plasma Arc Recycler

Our 500 kW D.C. plasma arc furnace offers a groundbreaking solution for aluminum melting, ensuring high yields, low energy consumption, and minimal waste. Designed for cost-effective foundry industry applications, it enhances steel quality, boosts productivity, and trims costs. With portability and versatility, this furnace is a powerful tool for various needs.

Reliability, flexibility, and robustness: Decades of experience culminate in the most adaptable design for secondary metallurgy.

Efficiency and compactness. We spent 15 years developing the most efficient technology of surface feeding for the best TCO in the most challenging conditions.

We spent 35 years developing a compact design that produces high performance and reliability.

Adapted for foundry or any treatment application where precision and repeatability are critical.

Lowest investments with compact technology—concentrated in innovative design.