From the simple process of adding and stirring reagents into hot metals, to sophisticated means of deep injection, Opta makes products used in all forms of ironmaking. We customize our products according to the requirements of each process with agents made of calcium oxide, calcium carbide, metallic magnesium, and others.

HOT METAL DESULFURIZATION

IRON DESULFURIZATION SOLUTIONS

Opta is the world’s leading supplier of magnesium reagents, calcium-carbide, and lime-based carrier reagents for use in the iron desulfurization process.

We offer injectable ironmaking desulfurizing products as well as injection and custom-built equipment.

We strive to ensure the highest levels of customer satisfaction.

Production involves precise technical diagnosis and application follow-up by our thoroughly qualified technicians.

Injectable Ironmaking Desulfurizing Products

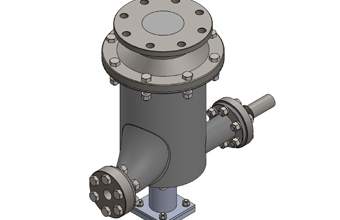

EQUIPMENT

Injection and Custom-Built Equipment

- Rotary Lance Injection

- Dual Lance Injection

- Multiple Outlet Injection

- Flow Control Valves

- Custom-Built Equipment

- Load Cell Calibration System

Our patented technology provides better dispersion of injection reagents leading to improved reagent efficiency, lower reagent consumption, reduced splash, and reduced temperature loss.

Lance injection systems such as our patented Dual Lance system reduce injection times, decrease temperature losses, and improve lance life.

Our patented system allows one injection system to inject through two lances for a smaller overall footprint when there are space constraints.

Patented valve systems such as our Variable Orifice Valve and Injection Nozzle Valve offer better control of reagent flow from injector vessels, paired with in-house PLC flowrate control software.

Includes Powder Injectors, Automated Tanker Unloading System, Temperature Sampler Drive, Lance Drive, Flowbin Stand, Slag Skimmer, Nitrogen Bubbler Lance Drive, Industrial Panels, and Pneumatic Conveyor Systems.

A single-button method for applying scale-calibration weights and avoiding carrying loads to the top of the injector; reduces injuries and ensures more regular calibration and, therefore, greater injector-weight accuracy.