Opta can enhance your process performance by applying technological innovation across various metallurgical needs. Our world-class engineers and scientists provide steelmakers with access to unsurpassed primary and secondary metallurgy expertise. As a result, Opta customers achieve metallurgical treatment consistency while decreasing cored-wire consumption.

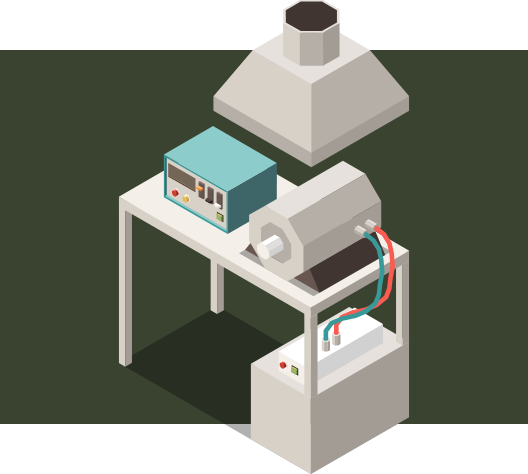

Our innovative tools help analyze nonmetallic-inclusion populations in terms of number, size, chemical compositions of inclusion phases, and spatial distribution of inclusions. We deliver results in many formats (comparison of number and size of inclusions, ternary diagrams, standard methods) in a complete evaluation report.