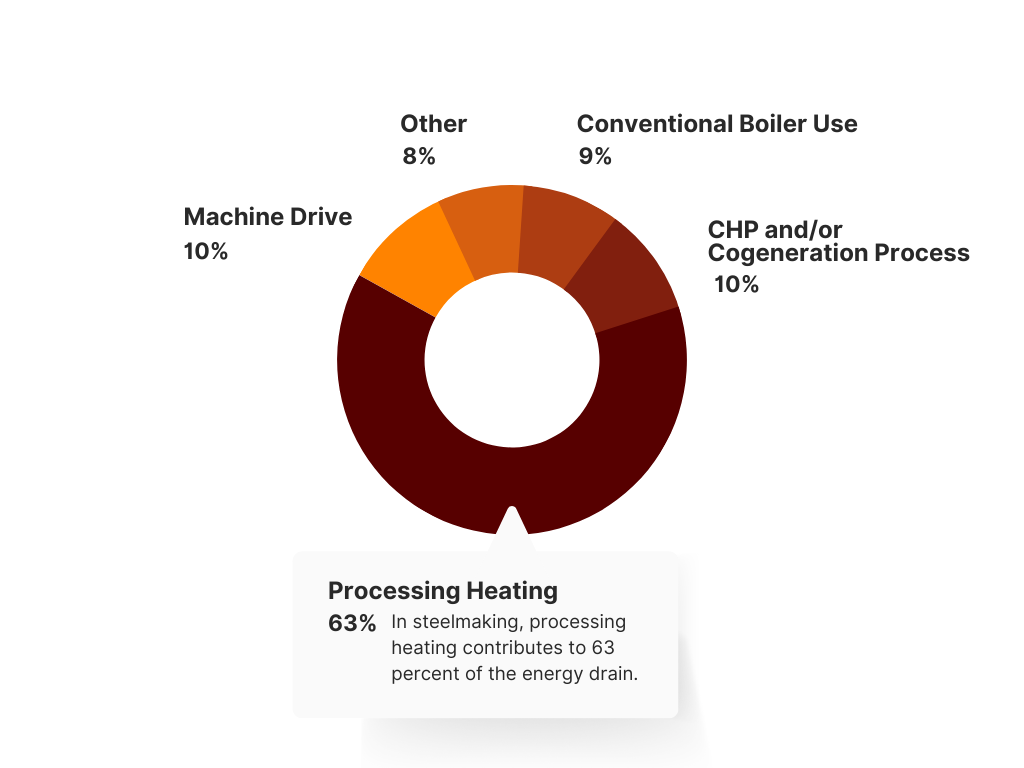

As an important, widely used engineering and construction material, steel is present throughout various aspects of our lives. Not surprisingly, steelmaking is highly carbon intensive, resulting in 1.8 metric tons of carbon dioxide emissions for every ton of steel produced.

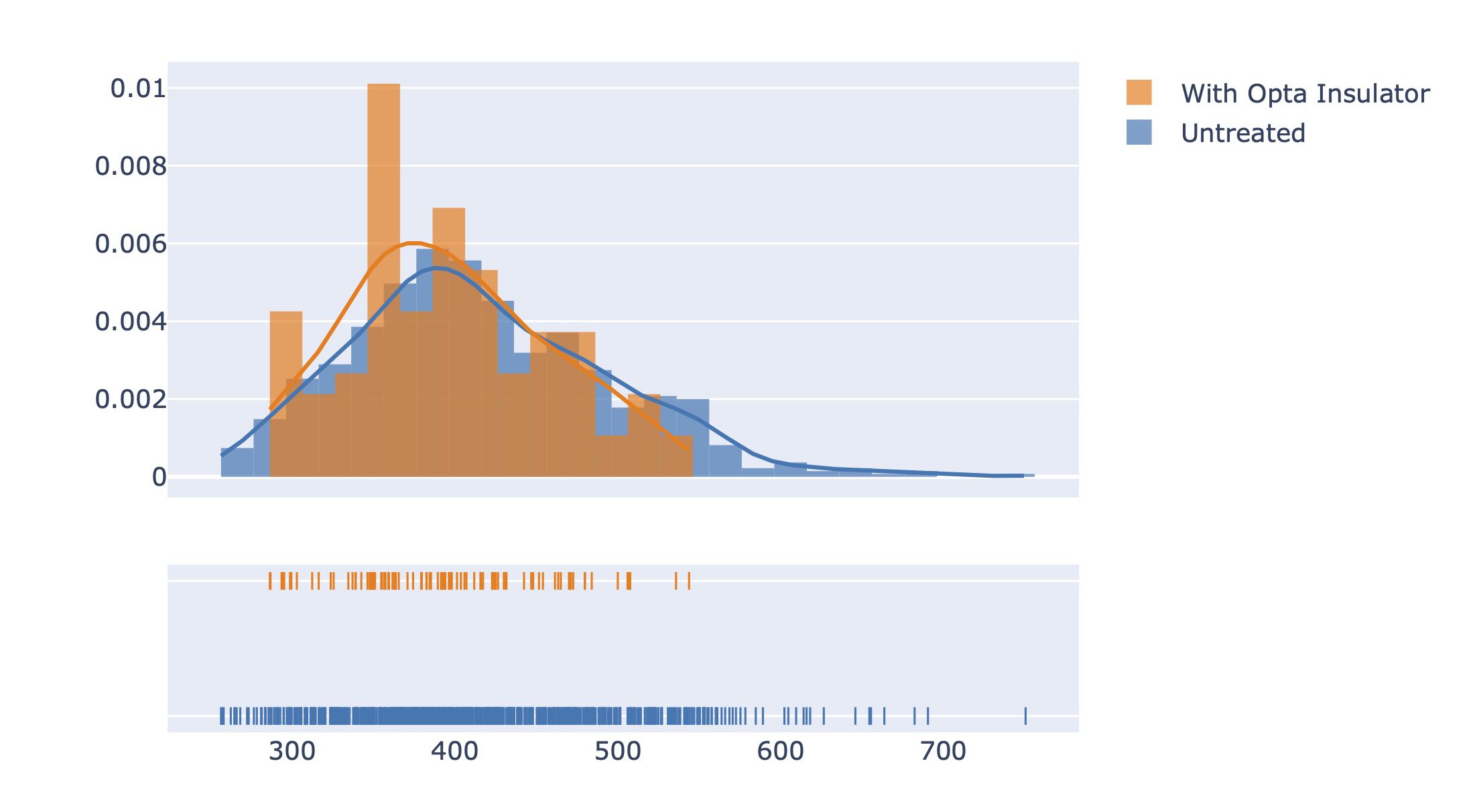

Accounting for roughly 8 percent of global CO₂ emissions, the steel industry ranks among the top three producers of carbon dioxide. As a result, steelmakers are increasingly confronting the challenge of decarbonizing their operations. Industry leaders recognize the need to reduce their carbon footprints and protect the global environment.

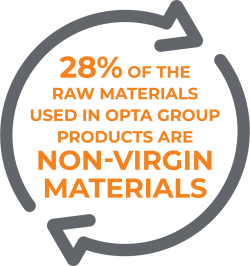

In response to customer demands for carbon-friendly products, manufacturers are striving to eliminate carbon emissions from their supply chains. Furthermore, tightening carbon emission regulations include reduced CO₂ targets and rising emission prices. And investors are exhibiting a growing interest in sustainability.